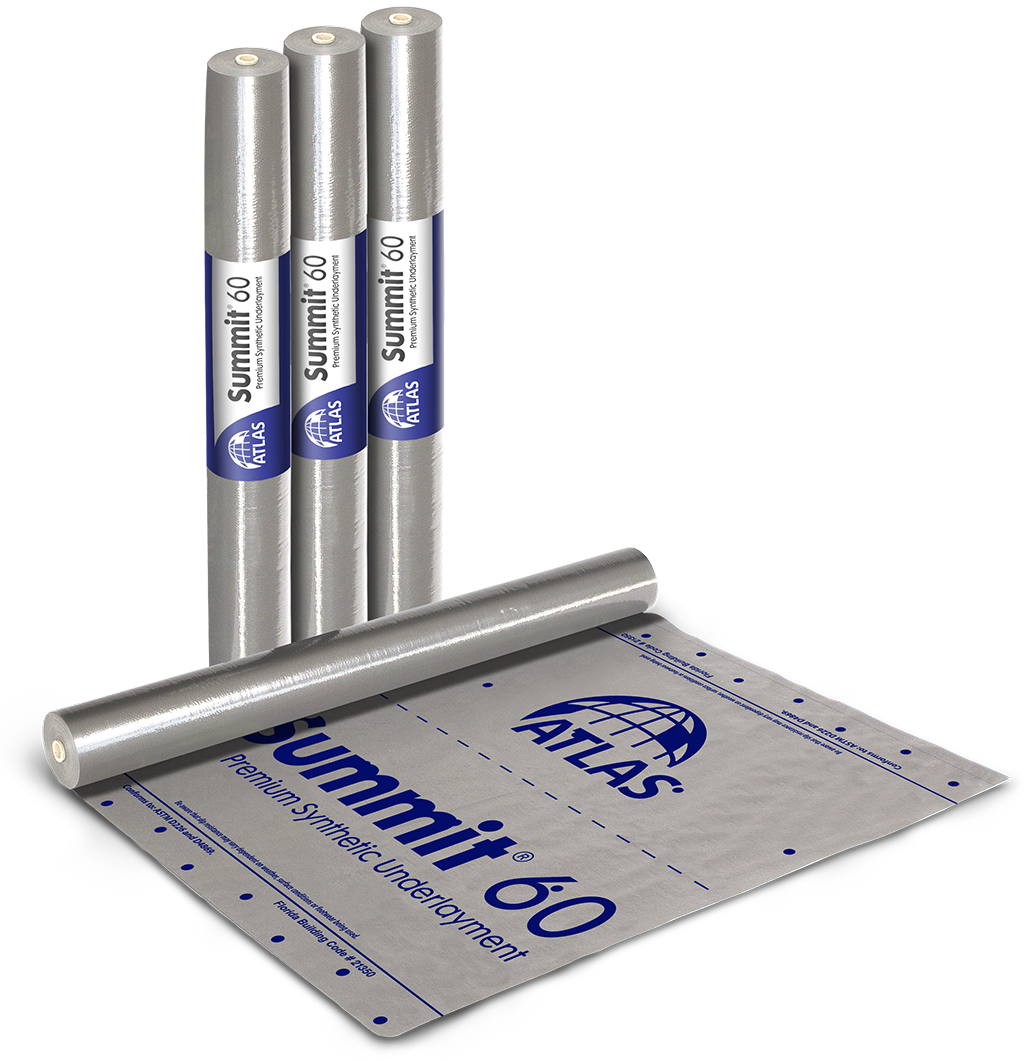

Summit® 60 is a lightweight synthetic roof underlayment designed as an alternative to #15 asphalt-saturated felt. It features a woven polymeric scrim for increased strength and reduced slippage between the underlayment and the roof sheathing. A textured top surface fabric improves walkability during installation. Summit® 60 can be mechanically fastened to various substrates, making it an excellent underlayment for new and re-roofing applications.

Summit® 60 is offered in 10-square rolls, providing more coverage per roll than traditional felt. It is manufactured with pre-printed lay lines for easy installation and offers 60-day resistance to UV breakdown.

FEATURES:

• 60-day exposure to UVSummit® 60 is designed to enhance the life of the roof and qualifies as an Atlas Signature Select® System Component.

Find A Contractor

Find A Contractor

Enter your zip code below to find a local Atlas certified contractor or to request a quote